Why would a WMS help improve customer service levels? Zofri, a new Infor WMS customer, tells us

What is Warehouse Management? Warehouse management is the process of overseeing all operations and activities in a warehouse. This generally includes receiving, picking, packing and shipping goods, planning workloads, training staff and handling customer returns. While warehouse management is barely visible to customers, it's integral to.

Wms Customer Presentation Stage 1 Introduction

3. Benefits of Warehouse Management Systems: Maximizing Efficiency with WMS. Growing businesses should consider the advantages of a warehouse management system, including but not limited to increasing warehouse productivity and saving costs. Let us go through the following list of benefits that make WMS a worthy investment for your business. 3.1.

What is a WMS? Streamline Logistics With Warehouse Management Systems

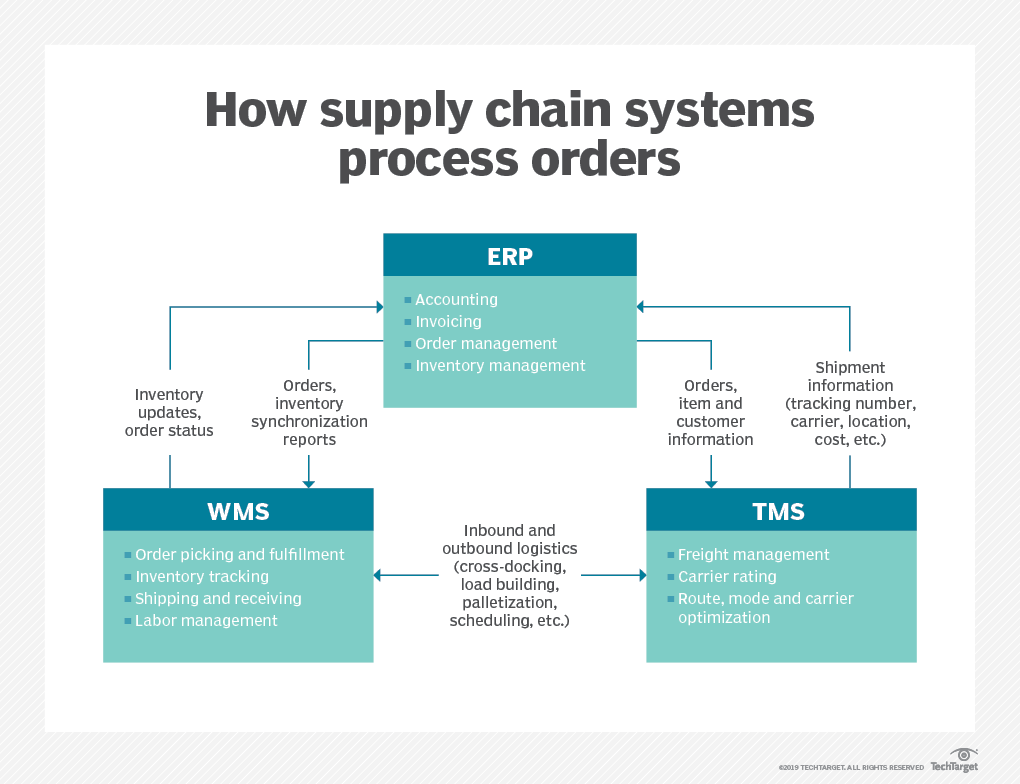

The WMS manages the data and processes relating to the movement of goods through a warehouse. Figure 1 shows each system's role in processing orders and the types of data they need to share with each other to ensure that the right product gets to the customer on time. The role of the WMS is to help users manage the fulfillment, shipping and.

Warehouse Management Systems (WMS) Features and Providers AltexSoft

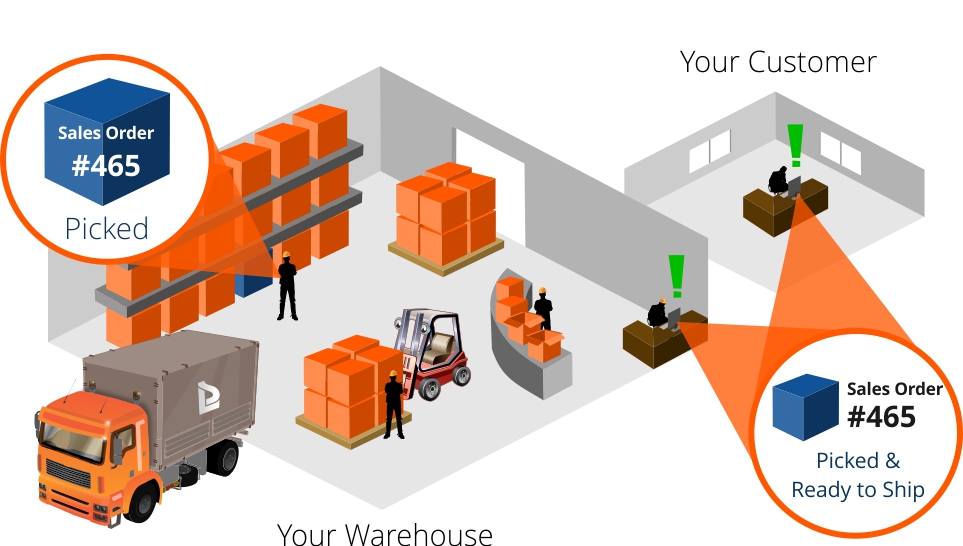

A warehouse management system (WMS) is software that helps businesses manage their warehouse operations. These systems make it easy to track everything happening in your warehouse, including what items are coming in, where they're stored, and where they're going. Warehousing management systems can help with: inventory tracking and management.

Introduction to Warehouse Management Systems (WMS) Technical Articles

A warehouse management system (WMS) is a type of software that is widely used in the manufacturing and retail industries because it tracks all materials and goods as they come in and go out of the.

Wms Customer Presentation Stage 1 Introduction

A warehouse management system (WMS) is a set of policies and processes intended to organise the work of a warehouse or distribution centre, and ensure that such a facility can operate efficiently and meet its objectives. In the 20th century the term 'warehouse management information system' was often used to distinguish software that fulfils.

Improving Customer Service Levels with WMS iCepts

NetSuite Warehouse Management System (WMS) optimises day-to-day warehouse operations using industry-leading practices, such as mobile RF barcode scanning, defined strategies for putaway and picking, task management, return authorisation receipts and cycle count plans. With hundreds or even thousands of SKUs to handle, often across multiple.

5 Ways Integrating WMS with ERP Improves Customer Service Supply Chain Management Solutions

Faster, more accurate order fulfillment directly correlates to customer satisfaction. A modern WMS consistently helps you exceed customer expectations and solve transportation issues with real-time tracking and analytics. 11. Energy Efficiency and Sustainability.

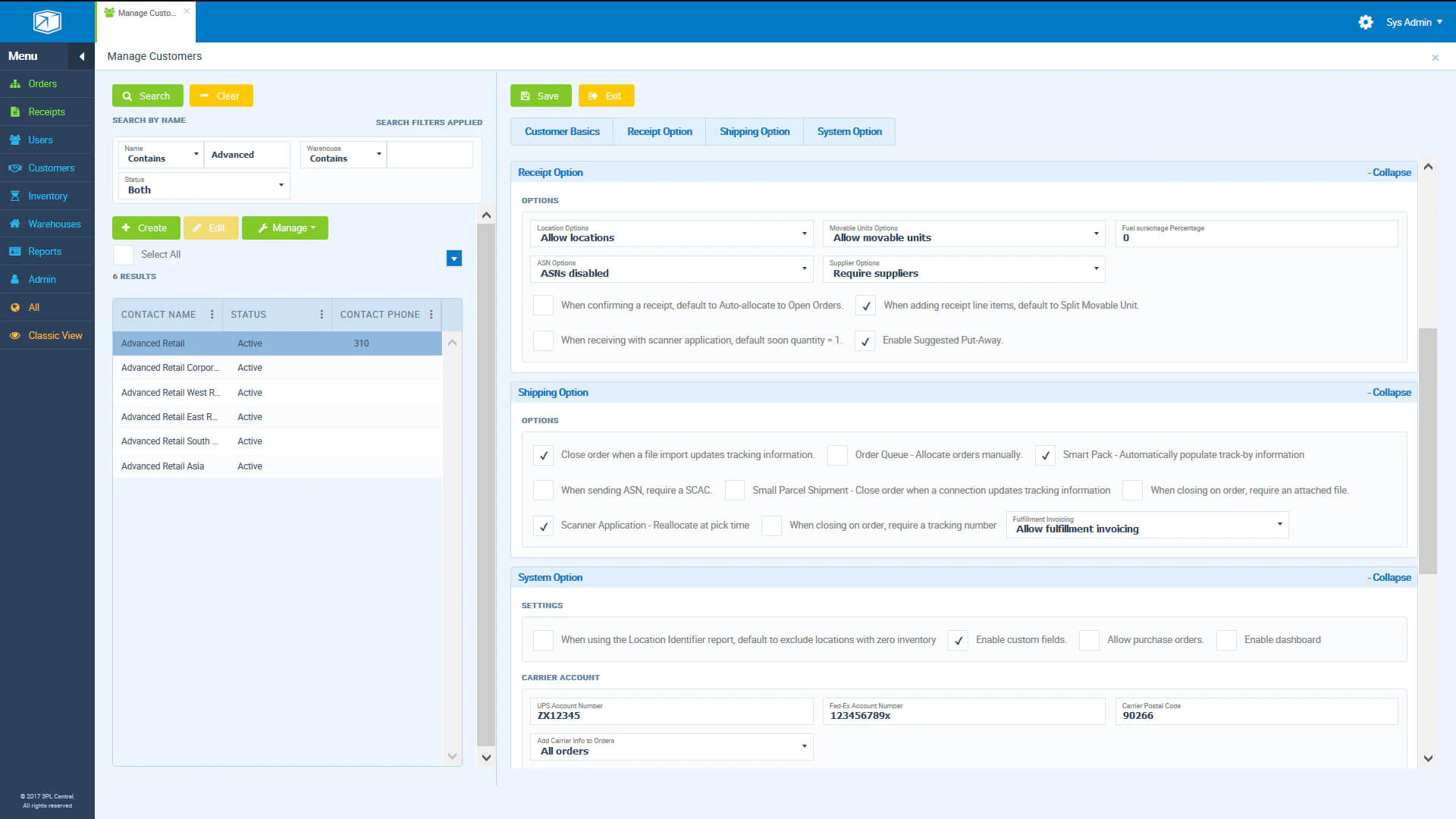

Customer Master Fast WMS Software

A WMS ERP module is natively integrated with a unified ERP solution that usually includes other modules for accounting, customer relationship management (CRM), human resources and inventory and order management. Since all warehouse data is stored in the shared database used by the other modules, everyone in the organization has access to the same up-to-date information at all times.

Can a WMS improve customer satisfaction? ProSKU

A modern WMS provides full enterprise-wide visibility of inventory and complete visibility of a product's journey from the warehouse to the store shelf (or a customer's front door). Supply chain technology and the overall supply chain ecosystem have faced numerous disruptions in recent years due to the pandemic and resulting ecommerce fulfillment boom.

Why you need WMS software for your B2B company Sequel Agency

WMS functions range from managing inventory, task interleaving, order picking, and allocation, to stock replenishment, packing, shipping status, labour management, and cycle counting. The kicker is that it automates these various warehouse tasks and provides real-time data and insights. This digitisation and automation are crucial in modern.

WMS (Warehouse Management Systems) Ground Handling

A warehouse management system (WMS) is software that streamlines every part of warehouse management - from receiving and storage to picking, packing, shipping, inventory tracking, and all the steps in between. A WMS helps companies increase operational efficiency and reduce waste and costs, while improving labor management and customer and.

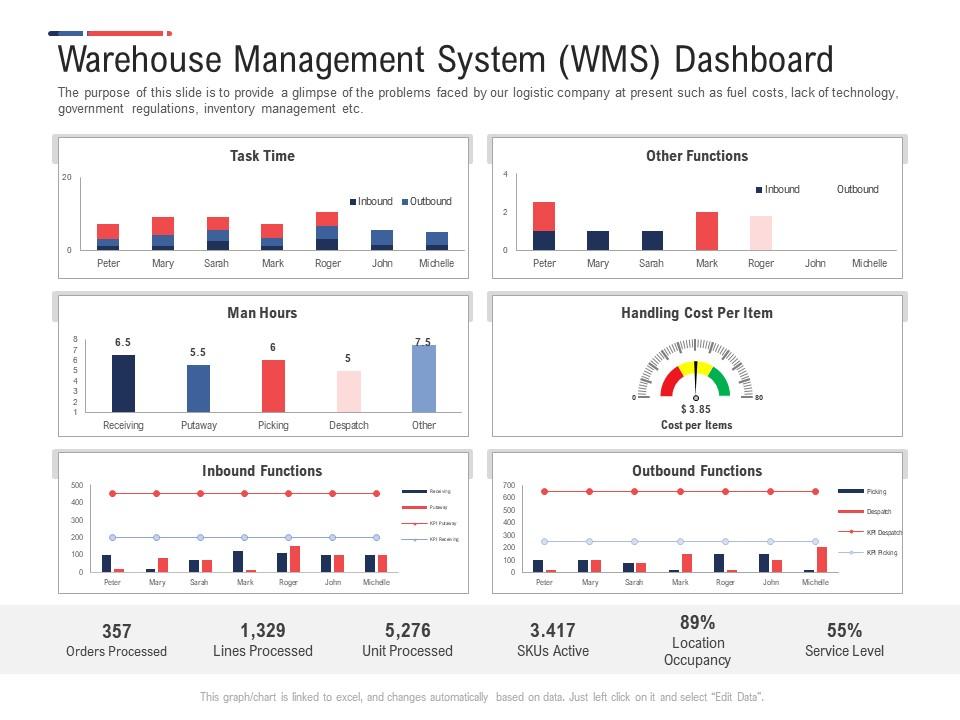

Warehouse Management System WMS Dashboard Inbound Outbound Logistics Management Process

Infor WMS helps me to manage all the products from warehouse to shelf. It's difficult to manage stocks in warehouse but the Infor Warehouse management software makes it easier. The best experience in Infor which is unique is the 3D visualization of the warehouse and software can be operated from any part of the world.

9 Ways To Guarantee a Successful WMS Implementation DEAR Systems

Benefits of Warehouse Management System (WMS). Building strong vendor and customer relationships is essential for ensuring consistent supply and demand fulfillment. A streamlined vendor experience translates to a better customer experience, especially in e-commerce. The WMS can consolidate orders from various sales channels and prioritize.

WMS O que é, como funciona e benefícios para a sua gestão

NetSuite Warehouse Management System (WMS) optimizes day-to-day warehouse operations using industry-leading practices, such as mobile RF barcode scanning, defined strategies for putaway and picking, task management, return authorization receipts and cycle count plans. With hundreds or even thousands of SKUs to handle, often across multiple.

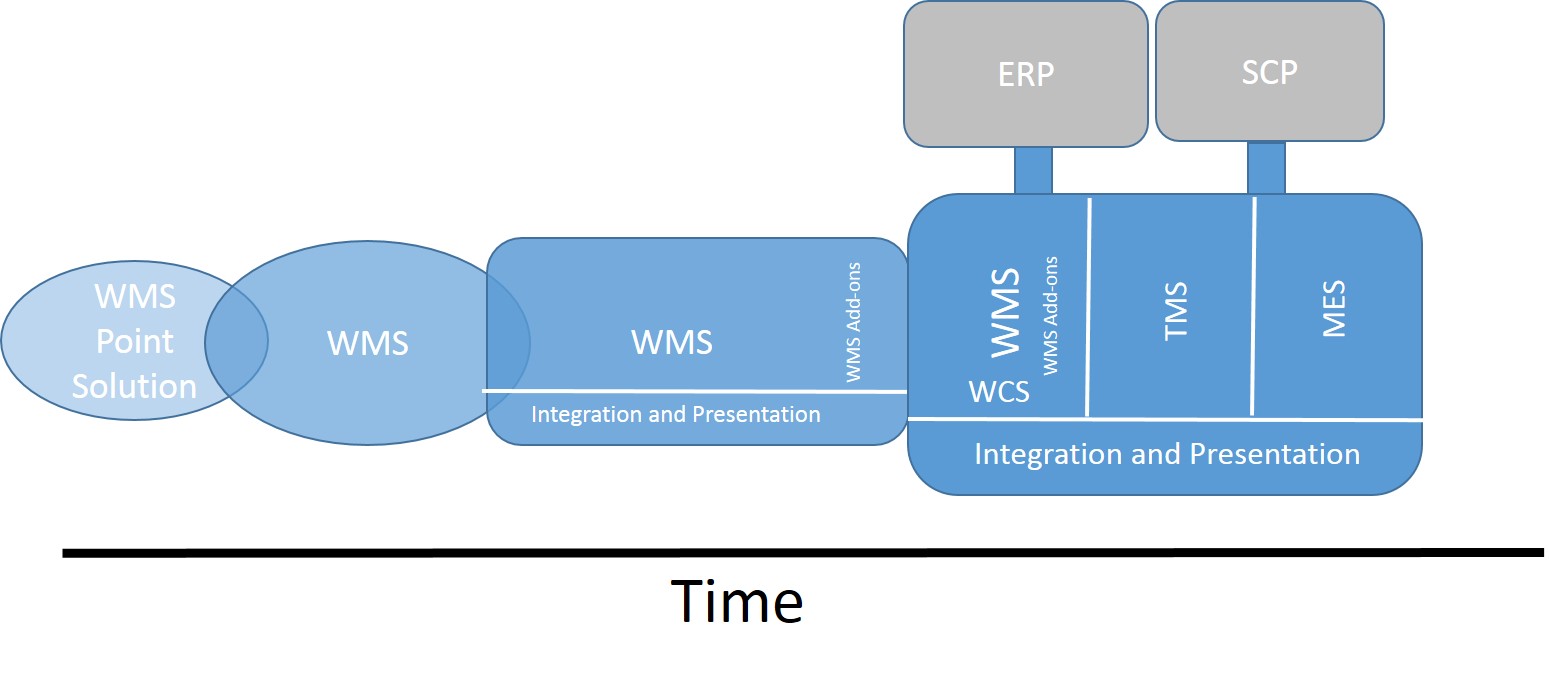

The Evolution of WMS Customer Requirements Logistics Viewpoints

A warehouse management system (WMS) is software that is designed and built to optimize the warehouse, distribution, supply chain, and fulfillment processes within a business. Typically, a WMS will provide functionality to help streamline and improve these warehouse processes, right from when goods first enter the warehouse, through the putaway.